CE460

Bar System

Cables Estructurales has a system of steel bars with its own design and manufacture to perform tie rods, these systems allow the adjustment or transmission of stresses in a simple and safe way in any type of structure.

The set of standard accessories, together with the possibility of customized manufacturing, allows the adaptation of the steel bar system to any requirement, both in dimensions and materials.

The use of the latest technologies in design and production facilitate a perfect adaptation to the specifications required by the engineering, requirements of the construction companies and being able to give advice and support in all the phases of the project.

Available Finishes

The selected steels have a high resistance with a low elastic limit and elongation percentage, due to the forming processes to which they are subjected.

Types of materials available for bar systems:

- CE460C: Black, Carbon Steel or Galvanized and painted.

- CE460I: AISI316 Stainless Steel, fine polishing with 240 grit sandpaper or mirror polishing.

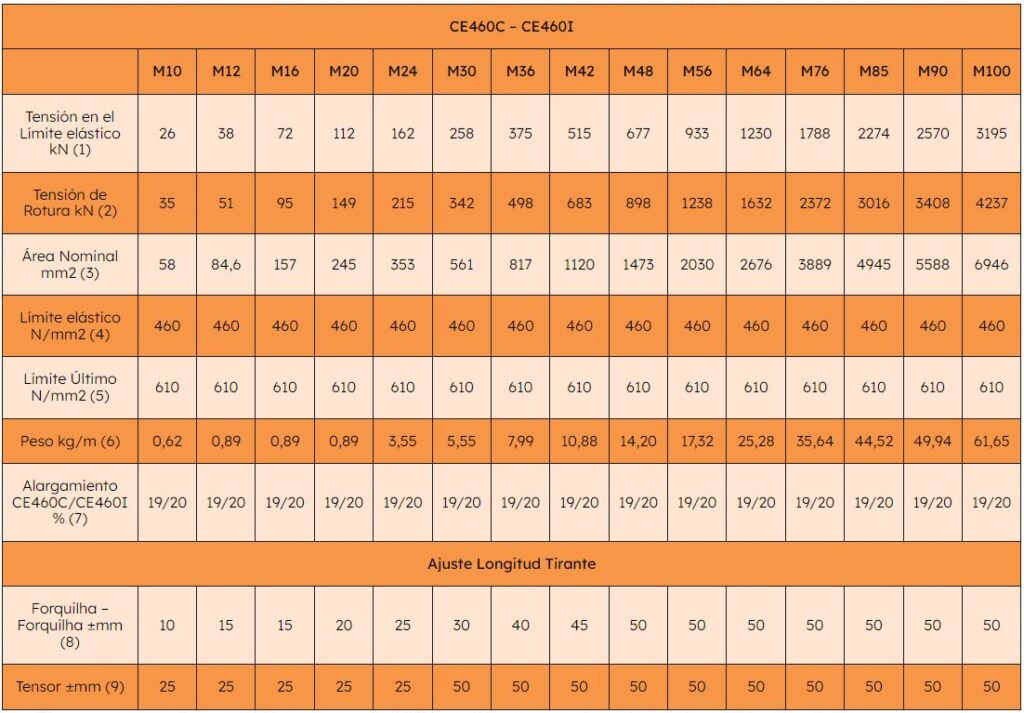

CE460 Mechanical Characteristics

CE460I

CE460C galvanized

CE460C natural

|

CE460C – CE460I |

|||||||||||||||

|

M10 |

M12 |

M16 |

M20 |

M24 |

M30 |

M36 |

M42 |

M48 |

M56 |

M64 |

M76 |

M85 |

M90 |

M100 |

|

|

Stress at Elastic Limit kN |

26 |

38 |

72 |

112 |

162 |

258 |

375 |

515 |

677 |

933 |

1230 |

1788 |

2274 |

2570 |

3195 |

|

Breaking load kN |

35 |

51 |

95 |

149 |

215 |

342 |

498 |

683 |

898 |

1238 |

1632 |

2372 |

3016 |

3408 |

4237 |

|

Nominal area mm² |

58 |

84,6 |

157 |

245 |

353 |

561 |

817 |

1120 |

1473 |

2030 |

2676 |

3889 |

4945 |

5588 |

6946 |

|

Elastic limit N/mm² |

460 |

460 |

460 |

460 |

460 |

460 |

460 |

460 |

460 |

460 |

460 |

460 |

460 |

460 |

460 |

|

Ultimate Limit N/mm² |

610 |

610 |

610 |

610 |

610 |

610 |

610 |

610 |

610 |

610 |

610 |

610 |

610 |

610 |

610 |

|

Weightkg/m |

0,62 |

0,89 |

0,89 |

0,89 |

3,55 |

5,55 |

7,99 |

10,88 |

14,20 |

17,32 |

25,28 |

35,64 |

44,52 |

49,94 |

61,65 |

|

Elongation CE460C/CE460I % |

19/20 |

19/20 |

19/20 |

19/20 |

19/20 |

19/20 |

19/20 |

19/20 |

19/20 |

19/20 |

19/20 |

19/20 |

19/20 |

19/20 |

19/20 |

|

Strap Length Adjustment |

|||||||||||||||

|

Fork ±mm |

10 |

15 |

15 |

20 |

25 |

30 |

40 |

45 |

50 |

50 |

50 |

50 |

50 |

50 |

50 |

|

Turnbuckle ±mm |

25 |

25 |

25 |

25 |

25 |

50 |

50 |

50 |

50 |

50 |

50 |

50 |

50 |

50 |

50 |

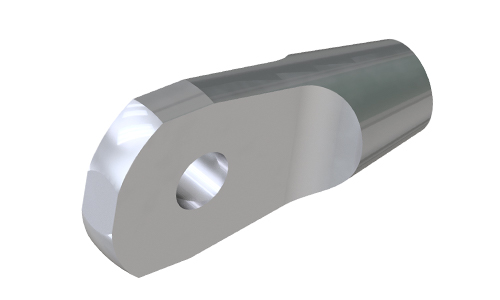

Features and Measurements CE460

Measures in millimeters.

Weight in grams.

| REF | M | D | A | H | L | B | Weight |

| 13.13.001_2.010 | M10 | 18 | 11 | 31 | 65 | 18 | |

| 13.13.001_2.012 | M12 | 18 | 12 | 47 | 90 | 22 | |

| 13.13.001_2.016 | M16 | 25 | 16 | 58 | 113 | 28 | |

| 13.13.001_2.020 | M20 | 30 | 19 | 75 | 132 | 33 | |

| 13.13.001_2.024 | M24 | 35 | 24 | 97 | 155 | 41 | |

| 13.13.001_2.030 | M30 | 43 | 30 | 111 | 189 | 52 | |

| 13.13.001_2.036 | M36 | 52 | 36 | 130 | 217 | 61 | |

| 13.13.001_2.042 | M42 | 60 | 39 | 148 | 238 | 69 | |

| 13.13.001_2.048 | M48 | 70 | 44 | 165 | 266 | 78 | |

| 13.13.001_2.056 | M56 | 80 | 49 | 176 | 315 | 95 | |

| 13.13.001_2.064 | M64 | 90 | 59 | 201 | 345 | 110 | |

| 13.13.001_2.076 | M76 | 110 | 76 | 234 | 410 | 132 | |

| 13.13.001_2.085 | M85 | 120 | 78 | 275 | 460 | 154 | |

| 13.13.001_2.090 | M90 | 145 | 86 | 289 | 485 | 162 | |

| 13.13.001_2.100 | M100 | 130 | 91 | 341 | 555 | 188 |

Measures in milimeters.

Weight in grams.

| REF | M | D | E | H | L | B | Weight |

| 13.13.003_4.010 | M10 | 18 | 8 | 31 | 65 | 18 | |

| 13.13.003_4.012 | M12 | 18 | 10 | 47 | 90 | 22 | |

| 13.13.003_4.016 | M16 | 25 | 12 | 58 | 113 | 28 | |

| 13.13.003_4.020 | M20 | 30 | 16 | 75 | 132 | 33 | |

| 13.13.003_4.024 | M24 | 35 | 20 | 97 | 155 | 41 | |

| 13.13.003_4.030 | M30 | 43 | 25 | 111 | 189 | 52 | |

| 13.13.003_4.036 | M36 | 52 | 30 | 130 | 217 | 61 | |

| 13.13.003_4.042 | M42 | 60 | 35 | 148 | 238 | 69 | |

| 13.13.003_4.048 | M48 | 70 | 40 | 165 | 266 | 78 | |

| 13.13.003_4.056 | M56 | 80 | 45 | 176 | 315 | 95 | |

| 13.13.003_4.064 | M64 | 90 | 55 | 201 | 345 | 110 | |

| 13.13.003_4.076 | M76 | 110 | 65 | 234 | 410 | 132 | |

| 13.13.003_4.085 | M85 | 120 | 75 | 275 | 460 | 154 | |

| 13.13.003_4.090 | M90 | 145 | 80 | 289 | 485 | 162 | |

| 13.13.003_4.100 | M100 | 130 | 90 | 341 | 555 | 188 |

Measures in millimeters.

Weight in grams

| REF | M | D | L | Weight |

| 13.13.012.010 | M10 | 10 | 22 | |

| 13.13.012.012 | M12 | 12 | 22 | |

| 13.13.012.016 | M16 | 16 | 28 | |

| 13.13.012.020 | M20 | 20 | 37 | |

| 13.13.012.024 | M24 | 24 | 44 | |

| 13.13.012.030 | M30 | 30 | 52 | |

| 13.13.012.036 | M36 | 36 | 64 | |

| 13.13.012.042 | M42 | 42 | 74 | |

| 13.13.012.048 | M48 | 48 | 86 | |

| 13.13.012.056 | M56 | 56 | 97 | |

| 13.13.012.064 | M64 | 64 | 120 | |

| 13.13.012.076 | M76 | 76 | 151 | |

| 13.13.012.085 | M85 | 85 | 159 | |

| 13.13.012.090 | M90 | 95 | 175 | |

| 13.13.012.100 | M100 | 110 | 180 |

Measures in millimeters.

Weight in grams.

| REF | M | D | L | Weight |

| 13.13.020.010 | M10 | 74 | 18 | |

| 13.13.020.012 | M12 | 78 | 18 | |

| 13.13.020.016 | M16 | 100 | 25 | |

| 13.13.020.020 | M20 | 140 | 30 | |

| 13.13.020.024 | M24 | 160 | 35 | |

| 13.13.020.030 | M30 | 160 | 43 | |

| 13.13.020.036 | M36 | 170 | 52 | |

| 13.13.020.042 | M42 | 185 | 60 | |

| 13.13.020.048 | M48 | 190 | 70 | |

| 13.13.020.056 | M56 | 215 | 80 | |

| 13.13.020.064 | M64 | 225 | 90 | |

| 13.13.020.076 | M76 | 250 | 110 | |

| 13.13.020.085 | M85 | 270 | 120 | |

| 13.13.020.090 | M90 | 280 | 130 | |

| 13.13.020.100 | M100 | 300 | 145 |

Measures in millimeters.

Weight in grams

| REF | M | D | L | Weight |

| 13.13.021.010 | M10 | 18 | 74 | |

| 13.13.021.012 | M12 | 18 | 78 | |

| 13.13.021.016 | M16 | 25 | 100 | |

| 13.13.021.020 | M20 | 30 | 140 | |

| 13.13.021.024 | M24 | 35 | 160 | |

| 13.13.021.030 | M30 | 43 | 160 | |

| 13.13.021.036 | M36 | 52 | 170 | |

| 13.13.021.042 | M42 | 60 | 185 | |

| 13.13.021.048 | M48 | 70 | 190 | |

| 13.13.021.056 | M56 | 80 | 215 | |

| 13.13.021.064 | M64 | 90 | 225 | |

| 13.13.021.076 | M76 | 110 | 250 | |

| 13.13.021.085 | M85 | 120 | 270 | |

| 13.13.021.090 | M90 | 130 | 280 | |

| 13.13.021.100 | M100 | 145 | 300 |

Measures in millimeters.

Weight in grams

| REF | M | D | L | Weight |

| 13.13.010_11.010 | M10 | 18 | 29 | |

| 13.13.010_11.012 | M12 | 18 | 30 | |

| 13.13.010_11.016 | M16 | 25 | 38 | |

| 13.13.010_11.020 | M20 | 30 | 42 | |

| 13.13.010_11.024 | M24 | 35 | 75 | |

| 13.13.010_11.030 | M30 | 43 | 105 | |

| 13.13.010_11.036 | M36 | 52 | 110 | |

| 13.13.010_11.042 | M42 | 60 | 120 | |

| 13.13.010_11.048 | M48 | 70 | 125 | |

| 13.13.010_11.056 | M56 | 80 | 135 | |

| 13.13.010_11.064 | M64 | 90 | 145 | |

| 13.13.010_11.076 | M76 | 110 | 155 | |

| 13.13.010_11.085 | M85 | 120 | 165 | |

| 13.13.010_11.090 | M90 | 130 | 170 | |

| 13.13.010_11.100 | M100 | 145 | 180 |

Measures in millimeters.

Weight in grams

| REF | M | D | H | E | Weight |

| 13.13.025.010 | M10 | 11 | 35 | 8 | |

| 13.13.025.012 | M12 | 13 | 40 | 10 | |

| 13.13.025.016 | M16 | 17 | 50 | 10 | |

| 13.13.025.020 | M20 | 21 | 70 | 15 | |

| 13.13.025.024 | M24 | 25 | 80 | 15 | |

| 2013.13.025.030 | M30 | 31 | 100 | 20 | |

| 13.13.025.036 | M36 | 37 | 120 | 20 | |

| 13.13.025.042 | M42 | 43 | 135 | 25 | |

| 13.13.025.048 | M48 | 49 | 150 | 30 | |

| 13.13.025.056 | M56 | 57 | 175 | 35 | |

| 4513.13.025.06450 | M64 | 65 | 200 | 40 | |

| 5513.13.025.076 | 60M76 | 77 | 240 | 45 | |

| 13.13.025.085 | M85 | 87 | 260 | 50 | |

| 13.13.025.090 | M90 | 92 | 280 | 55 | |

| 13.13.025.100 | M100 | 102 | 320 | 60 |

Mounting

Fastening of fork-fork bar tie rod with intermediate turnbuckle to anchor plates by means of pins.

Screw conical nuts on the bars, orienting the conical area towards the bars, both in the area of the forks and in that of the turnbuckle; always paying attention to the orientation of the thread (right thread or left thread).

Screw the forks and turnbuckle. The minimum length of threading: - M10 to M56: 1.5 times the thread diameter -M64 to M100: 25 mm + 1 times the thread diameter.

Thread the flare nut against the clevis and tighten.

Now the tie rod is prepared for the assembly of the pins in the fork with the anchor plate.

Adjustment of the length of the tie rod with the turnbuckle, by turning it.

Tighten the flare nuts against the tensioner.

Request budget

Request information about our products through the form. Fill in the requested fields and tell us the types of products you are interested in. We will contact you as soon as possible to advise you.